Project:

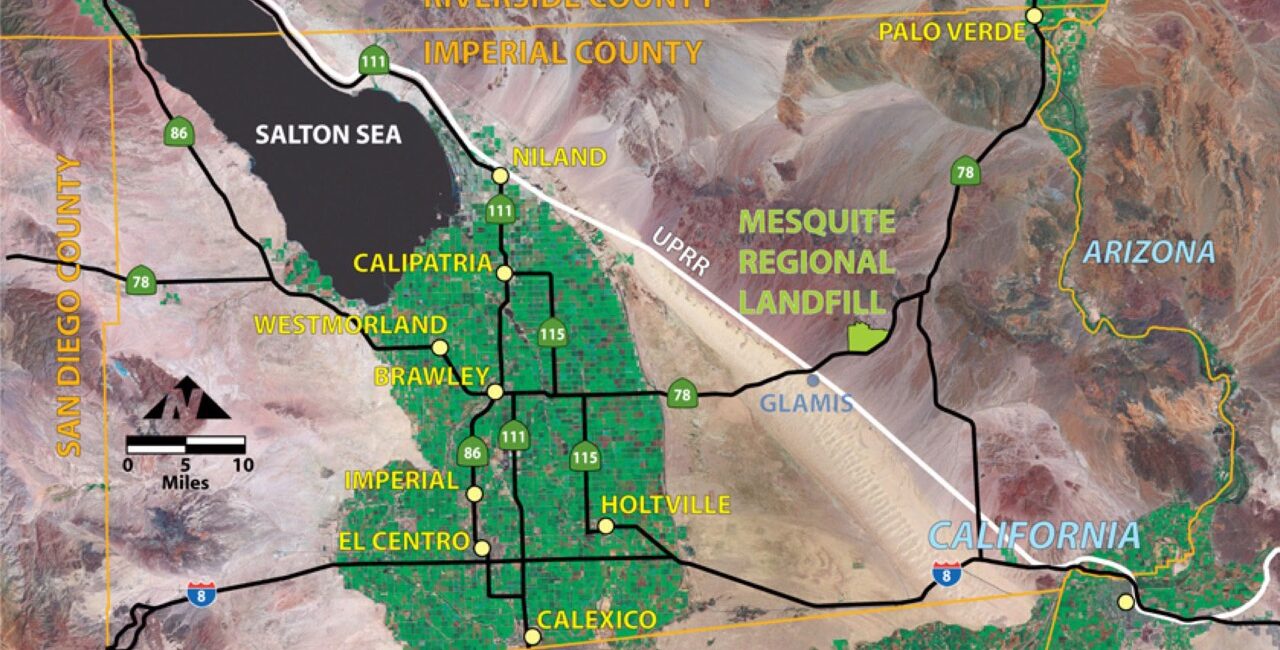

Mesquite Regional Landfill – Geotechnical Characterization, Master Planning, Preparation of Permit Documents, Preparation of Technical Design Report, and Alternative Final Cover Study

Scope of Services Provided by AES

AES performed extensive geotechnical studies for this 2,300-acre, 600-million-ton mega landfill site for waste-by-rail haul involving 167 borings for a total of 10,265 linear feet and 244 test pits for Master Plan phase design and material sources evaluation.

Master Plan Studies – Included fill sequencing, liner and LCRS design, stockpile management, waste handling, soil handling, cell development, intermediate and final cover, performance monitoring systems, drainage facilities, landfill gas collection system, liquids collection and treatment, intermodal yard, rail yard and rail spur, service, maintenance, and administration facilities, and site infrastructure.

Clay Resources Evaluation – Drilling, logging, and sampling of 69 borings up to 100 feet deep and 18 test pits; geophysical survey using electric resistivity and seismic refraction methods; evaluating processing needs to obtain the maximum yield of acceptable material; and estimating overburden removal.

Sand and Gravel Deposit Evaluation – Included 51 bucket auger borings and 47 test pits to evaluate the quality and quantity of sand and gravel for various landfill uses, including LCRS gravel, concrete aggregate, LFG trench backfill, road base material, and railroad ballast; characterizing in situ properties of sand and gravel to evaluate its compressibility under 450 feet of refuse and to estimate the removal depths to control settlement.

Laboratory tests included aggregate quality tests (soundness, abrasion, alkali reactivity, petrographic analysis). The results of field and laboratory tests were used to determine the processing method, including screening and washing plant and handling byproducts of processing.

Mine Waste and Leach Pads Evaluation – Field investigation of the soil stockpiles consisted of 113 million cu. yds. of mine run material and 97 million cu. yds. of heap leach pad materials used to mine gold, including drilling 36 borings and 166 test pits. The leach pads were investigated by 7 sonic borings and 13 test pits. Performed gradation and aggregate quality tests to evaluate processing needs, anticipated yield, and to size the processing plant.

Infrastructure Foundations –Foundation and grading recommendations for site facilities, including administration building, rail spur, and weigh scales, including evaluation of seismic design values for siting the structures.

Preparation of Technical Design Report (TDR) for Cell Design – Preparation of TDR summarizing results of investigation and design of the liner system, LCRS and surface drainage for regulatory agencies review, including RWQCB, CIWMB and California Department of Water Resources (DWR) to secure permit for opening of the waste-by-rail landfill and start of construction of the first composite liner cell. The scope also included performing equivalency demonstration analysis for LCRS, vadose zone monitoring and alternate cover evaluation.

Alternative Final Cover Study – Geotechnical and engineering design services for alternative final cover, an evapotranspirative cover (monocover) for side slopes and top deck. This included field exploration and sampling of potential onsite cover sources; laboratory preparation of representative cover samples by reconstituting materials to represent average gradation; laboratory testing for unsaturated characteristics; performing water balance modeling for cover percolation; static and seismic slope stability analysis of cover veneer; and erosion resistance evaluation. Alternative Final Cover study involved modeling to allow use of large size (up to 12-inch) material for side slope cover.

Accomplishments / Commendations

Our innovative alternative cover design using up to 12-inch size materials resulting in millions of dollars savings in processing costs received recognition from a renowned geotechnical expert, who peer reviewed the design:

“I review a variety of reports each year, and few are written as well as this one.…. This is an excellent report….Your analysis of the lab data is excellent. I would like to write/ co-author a paper on the lab work. Please let me know if that is of interest.”

Our high-quality deliverables also earned this commendation from the client:

“Suji, you and the entire AES Team involved with this Mesquite Regional Landfill Final Cover evaluation project have done an exceptional and outstanding job in my opinion. I have come to recognize during the review process, the incredibly hard work that AES has done on this project, performing geologic field work at the site, then doing very sophisticated state-of-the-art geotechnical engineering modeling, and summarizing them in two well written documents.”